Case Study – IOCL Panipat

Customer Introduction

IOCL PANIPAT REFINERY is a technically advanced public sector refinery complex in India.

Problem/Goal

In order to meet the growing demand of petroleum products Panipat Refinery Additional Expansion Project (PRAEP) was established to increase refining capacity from 12 MM TPA to 15 MMTPA through utilization/revamp of existing units.

M/s. IOCL Panipat approached M/s MT Pl to carry out the adequacy check for Amine Regeneration unit (ARU) column to handle the increased flow capacity from 409 Kg/M3 to 450 Kg/M3.

Solution

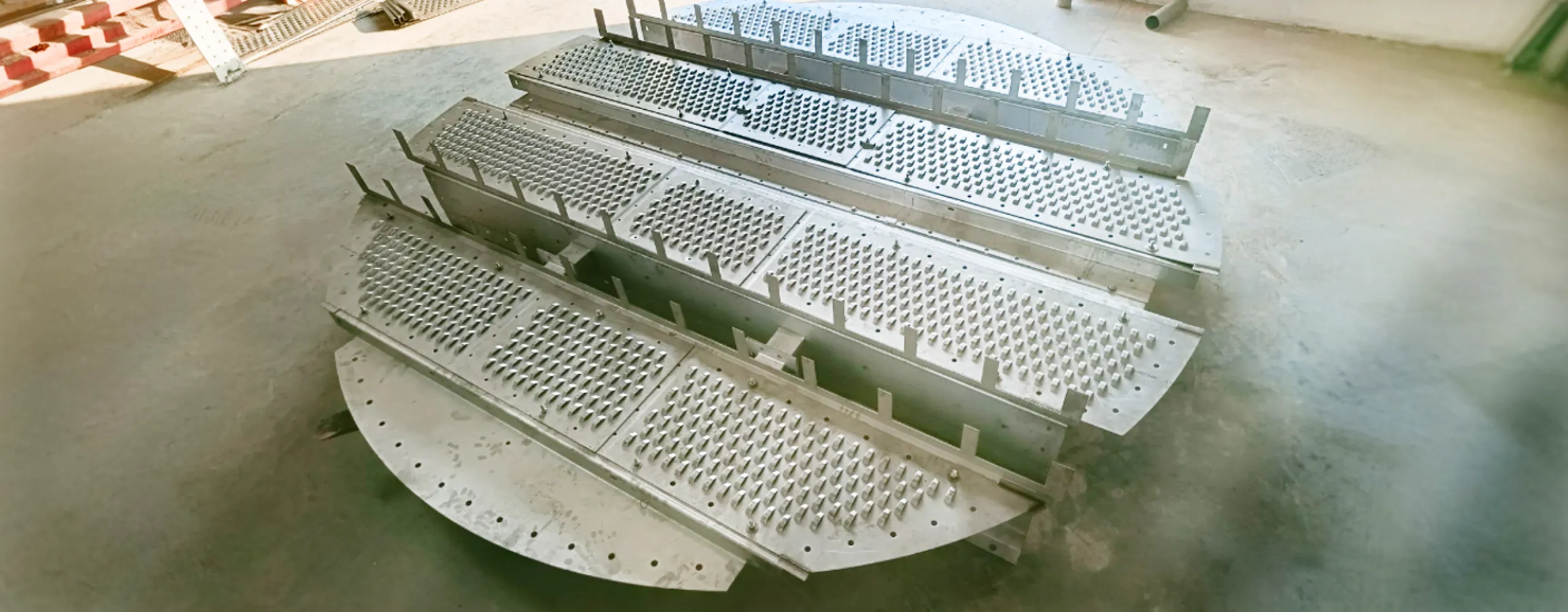

MTPI performed hydraulic studies based on tray loading data and identified trays with limitation of jet flooding and some trays with limitation of weir loading. Based on this MTPI recommended using High Capacity Trays to address this problem.

Result

MTPI then designed and supplied proprietary MTPI High Capacity Trays to IOCL Panipat who achieved a 15% expansion in capacity of the ARU.

Inspiration

MTPI is proud to be associated with the strong team of IOCL and is committed to identifying optimum solutions for our customer needs.

Customer Speaks

Performance of the products designed and supplied by MTPI for the Amine Regenerator Unit are extremely satisfactory. Extremely professional and polite team providing supervision and after sales services