Our Products

Tower Internals

The importance of column internal design is often overlooked in most packed column designs. Vapour and liquid distribution are of critical importance to ensure the efficient performance of distillation columns. MTPI has a wide range of column internals which include liquid/vapour distributors, collector trays, and packing supporting/retaining devices. MTPI offers services for design and selection of suitable and efficient tower internals for any application. MTPI designs and manufactures tower internals in all metals such as CS, SS 304, SS 304L, SS 316, SS 316L, SS 410, SS 430, Monel, Titanium etc. and engineering polymers such as PFA, PVDF, ECTFE etc. and plastic such as PP, HDPE, etc.

Packed tower design is based on the fundamental concept of equal liquid and gas distribution across the column section. The pressure drop across the packing provides an impetus for the upward flowing gas to become uniformly distributed across the column area. A packed bed irrigated by an optimally designed distributor allows the process to realise it’s full separation potential (number of stages) of the packed bed. To get the optimum Mass Transfer in the packed bed, distribution of both liquid and gas is important.

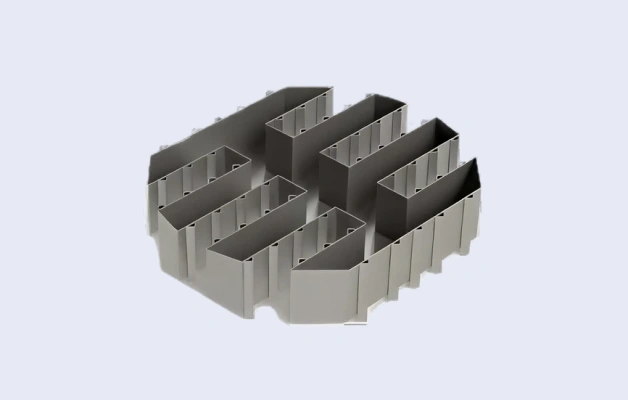

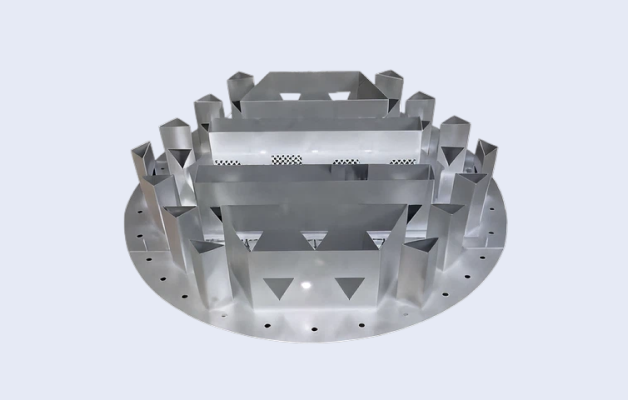

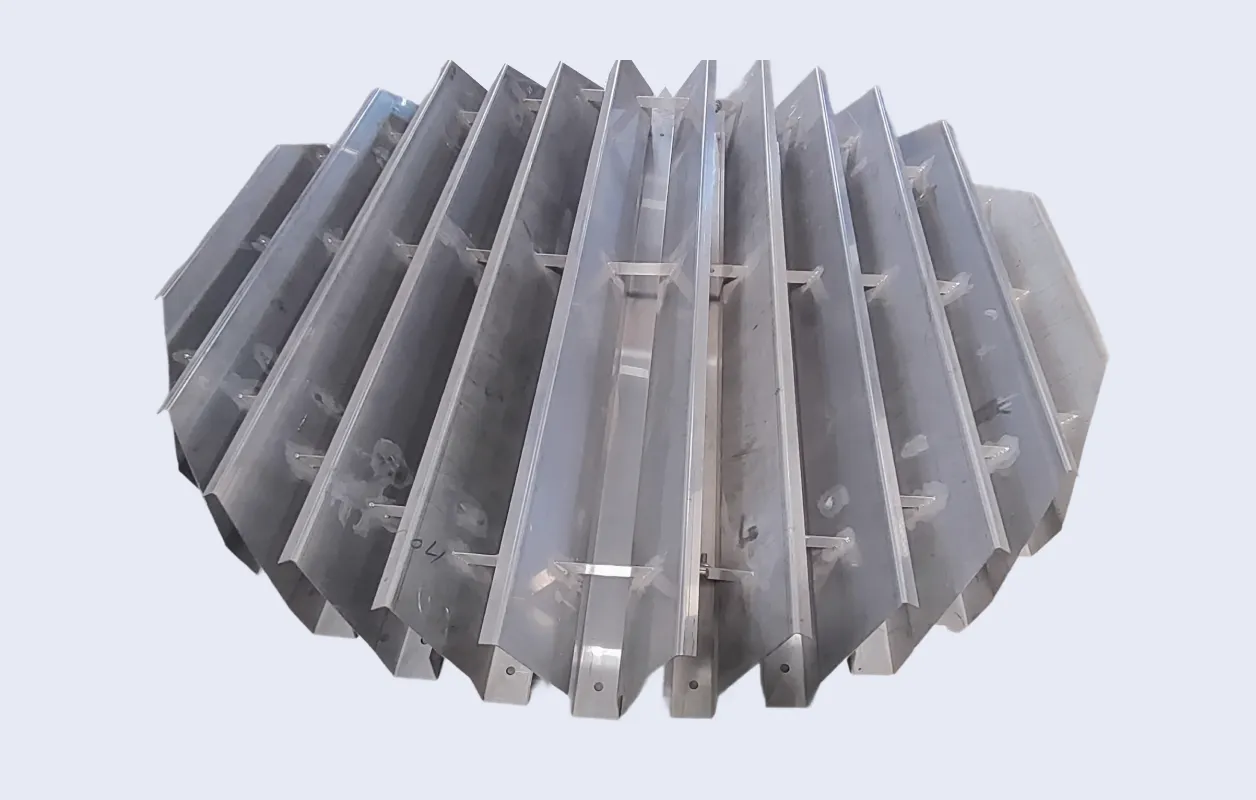

Deck Type Distributor

This type of distributor has drip points on the deck surface along with protruded risers for gas to escape. In case of redistributor riser covers are provided to prevent liquid entering into the gas riser. These distributors can be one piece / multi piece construction with gasketted joints depending on column diameter.

Pan Type Distributor

This type of distributor is used when the column diameter is fairly small. They are fastened with column clips and provide higher open area for gas flow. Pan Type distributors / redistributors can be single piece / multi piece construction.

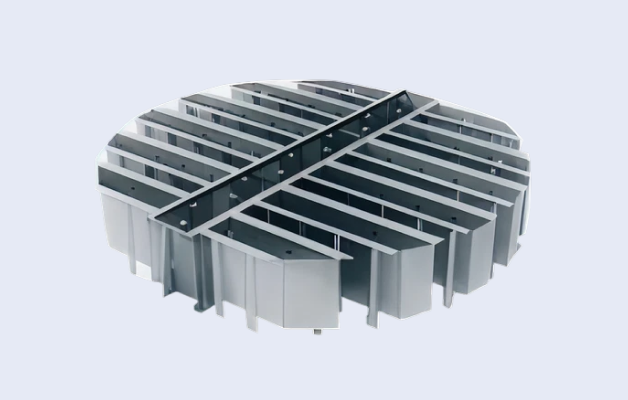

Trough Type Distributor

Trough Type Parting Box

Trough Sump Distributor

V Weir Notch

Flow Multiplier

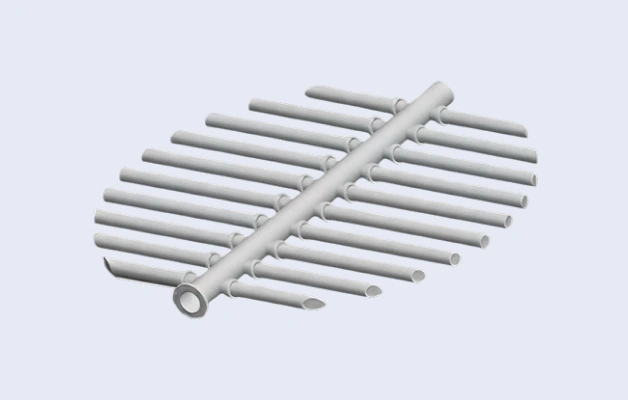

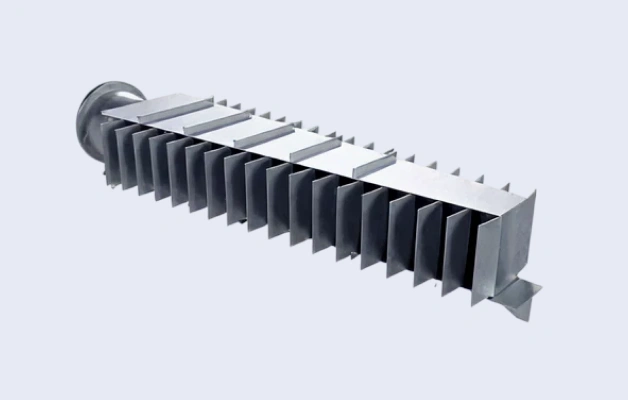

Header Lateral

Spray Nozzle

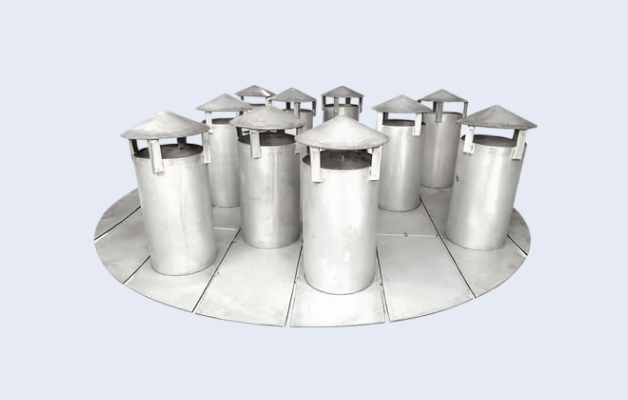

A collector tray, also known as a chimney tray collects liquid for drawing off a product, or pump around stream, or combining with a liquid feed or ensuring uniform distribution across the tray area or improving mixing. These can be manufactured in metals, plastics and FRP.

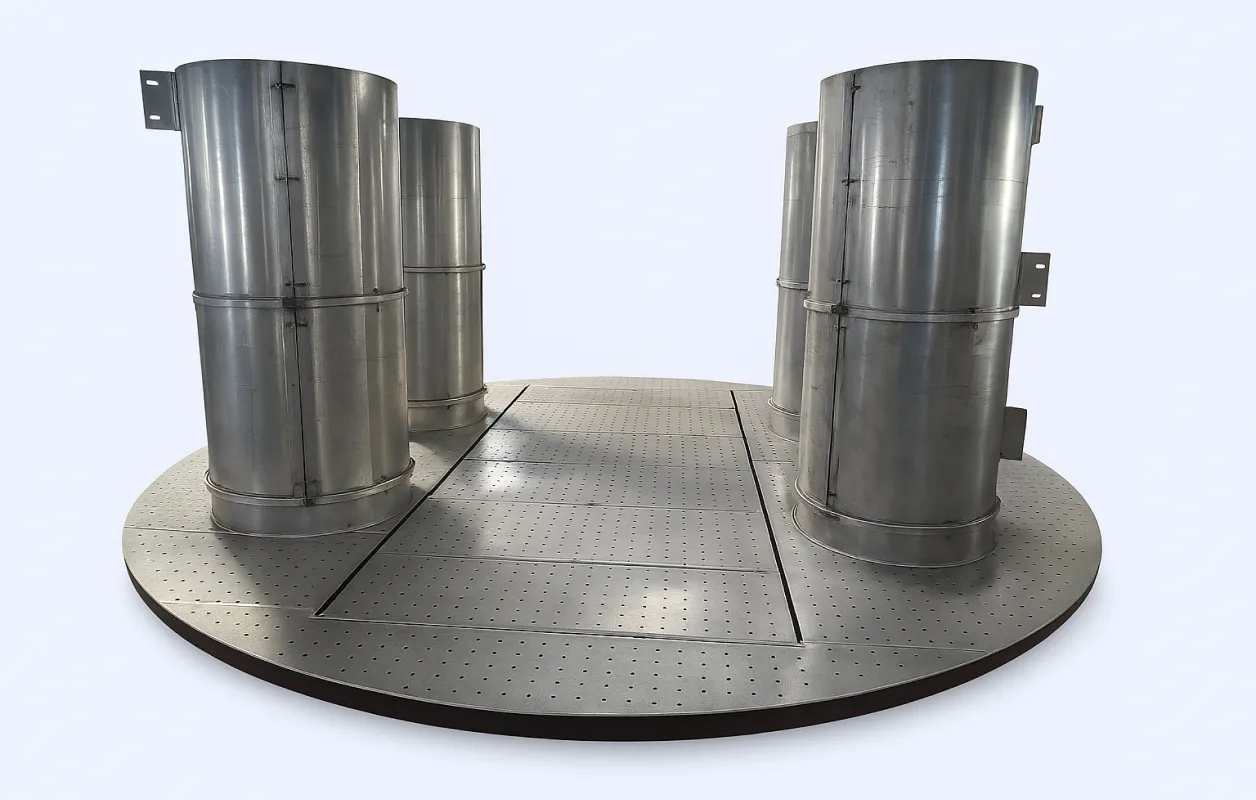

Chimney Collector Tray

Vane Type Collector

Vapour Inlet Device

Gallery Tray

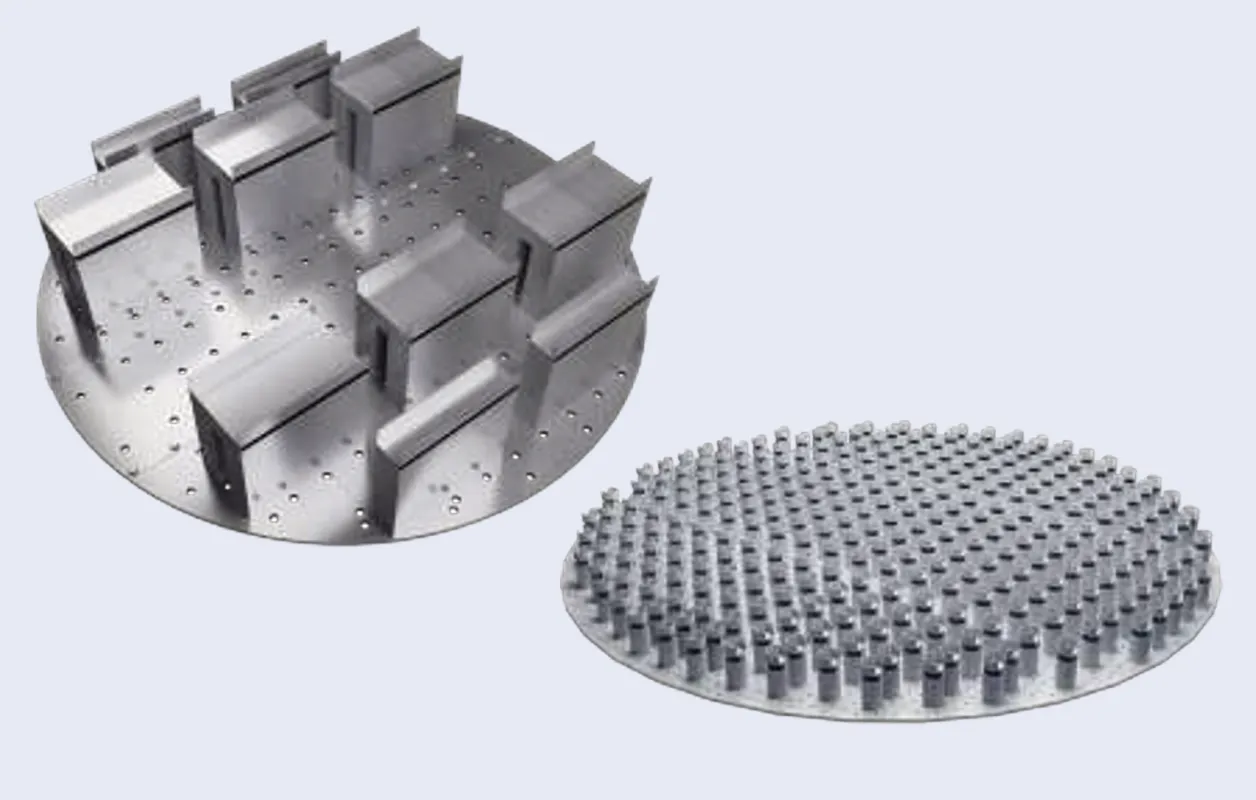

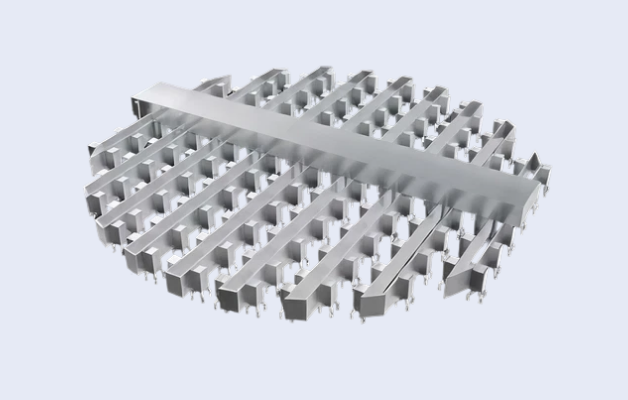

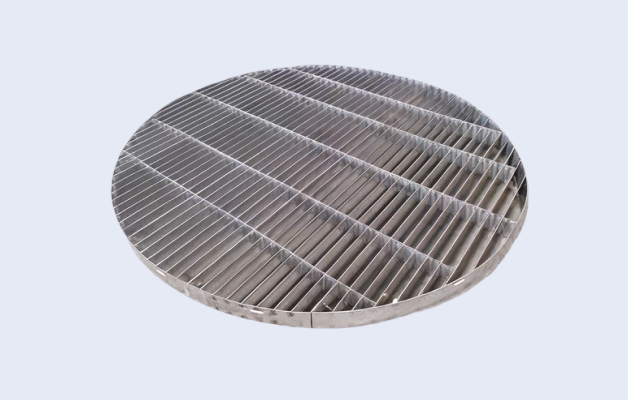

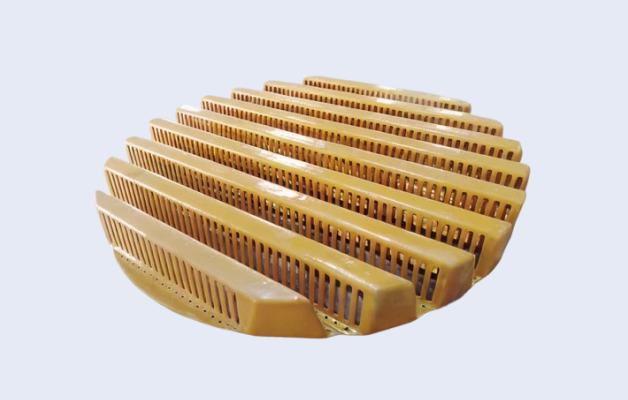

Bed limiters and hold down plates are retaining devices used above packed beds to prevent fluidization and restrict packing movement, which can occur during upset conditions. Bed limiters are used for metal and plastic random packings as well as structured packing. Hold down plates are used for ceramic and carbon packing. They rest directly on the packing and prevent packing from breaking up due to fluidization when operated at high pressure drops or during temporary surges. These can be manufactured in metals, plastics and FRP.

Bed Limiter

Hold Down Grid

Bed Limiter FRP

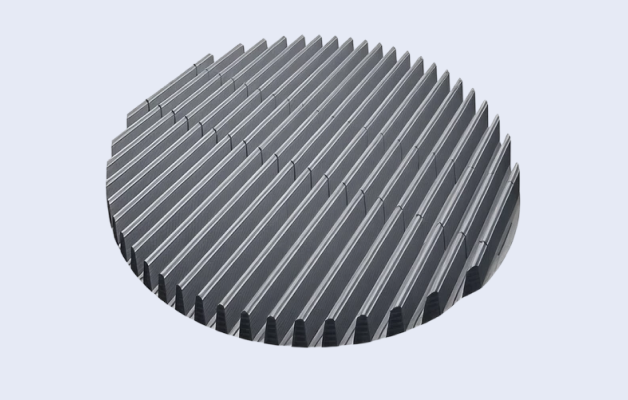

Support plates are provided to physically support the cumulative weight of the random/structured packing and the operating "liquid hold-up" in the packed bed. Support plates are shaped and designed to provide maximum open area and minimal pressure drop. These can be manufactured in metals, plastics and FRP.

Support Plate Metal

Support Plate Plastic

Support Plate FRP

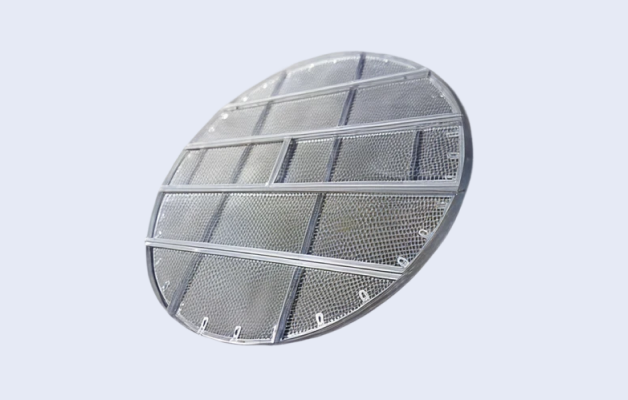

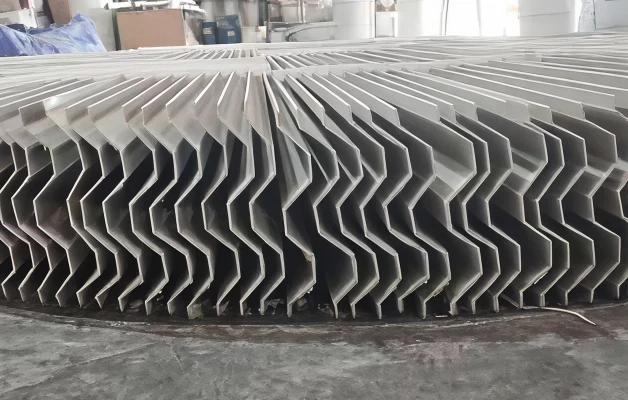

Mist elimination, or the removal of entrained liquid droplets from a vapour stream, is one of the most commonly encountered processes of unit operation. Droplets are removed from a vapour stream through a series of three stages: collision & adherence to a target, coalescence into larger droplets, and drainage from the impingement element. These can be manufactured in metals and plastics.

Mist Elminiator Metal

Mist Elminiator Plastic

Vane Type Plastic

Contact Us

Whether you’re looking for product support, a custom order, or just more information — our team is ready to assist you.