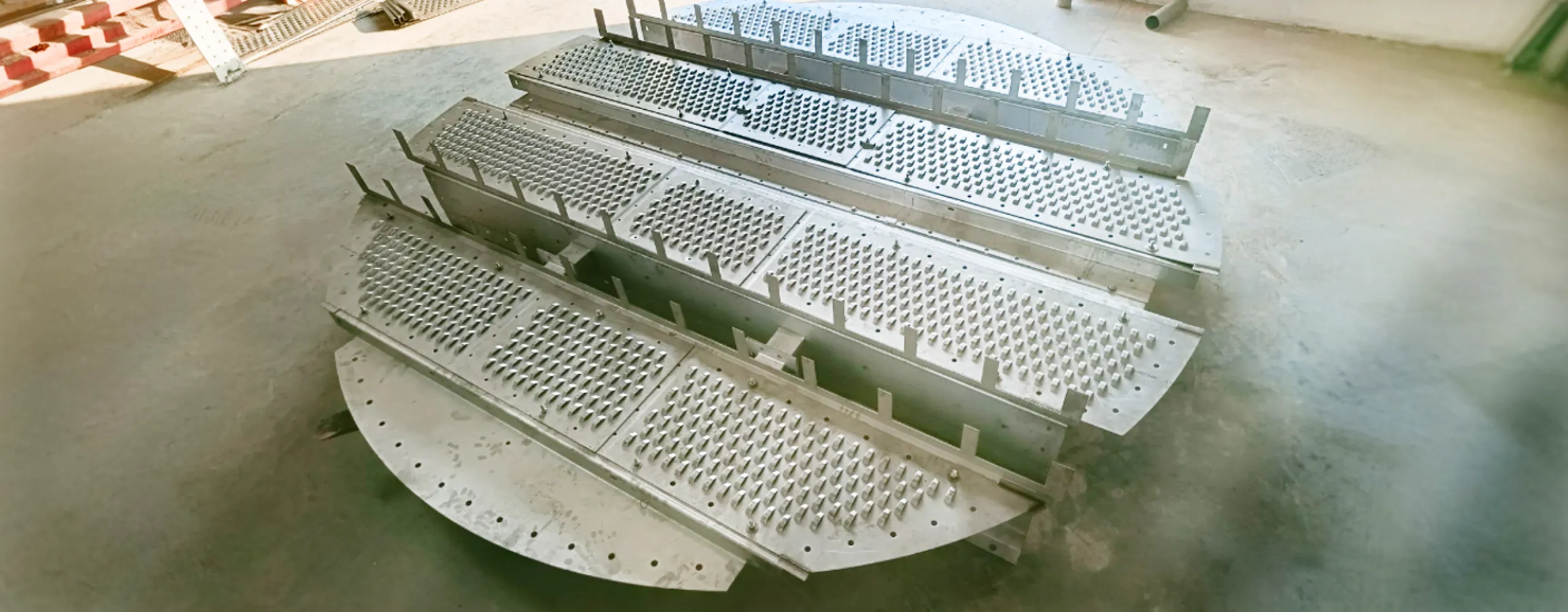

When it comes to distillation, absorption, stripper or scrubber columns, there is no one-size-fits-all approach.

When it comes to distillation, absorption, stripper or scrubber columns, there is no one-size-fits-all approach. Trays and packings both have their advantages; the key is choosing what best fits your process.

🔹 Efficiency: Packings provide large continuous surface area and improve mass transfer efficiency in less height. However, trays frequently provide more consistent stage-wise performance across a wide range of operation.

🔹 Pressure Drop: Packings win in vacuum or low-pressure systems thanks to minimal pressure drop. Trays, however, handle variations in vapor/liquid flow much more gracefully.

🔹 Fouling: Trays are commonly used for services with foaming or fouling. Packings perform well in clean systems with consistent operating conditions.

🔹 Loading: Trays can accommodate large liquid flow rates without flooding. The capacity of packings tend to rapidly fall off at high liquid rates. It is often more economical to handle high liquid rates in tray columns.

🔹 Maintenance & Cost:

Trays are easier to inspect and maintain. Packings reduce energy use and offer compact column designs — great for revamps or tight layouts.

✅ Takeaway:

It’s not about which is better — it’s about what’s right for your service. The smartest designs balance efficiency, reliability, cost and practicality.

References:

Distillation Design by Henry Z. Kister

Applied Process Design for Chemical and Petrochemical Plants Vol 2, by Ernest E. Ludwig

#ChemicalEngineering #ProcessOptimization #Distillation #EngineeringDesign