Trays are commonly used for oil refineries and applications where pressure drops are not critical. Conventionally columns operating under high or moderate pressures can be designed for trays for distillation purpose. Tray columns can also be designed to operate under atmospheric or partial vacuum or complete vacuum conditions.

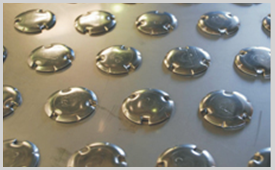

Valve Trays

Valve Trays have caps over the perforation on the trays. These caps are either fixed or floating. Fixed valves are set at a defined height and remain in open condition. The floating valves are either circular or rectangular and move up and down based on the vapour pressure. Floating valve trays are more efficient than fixed valve trays.

Bubble Cap Trays

These trays consist of deck with fitted risers on which, inverted caps are fixed keeping a gap for vapour passage. This results in greater pressure drop. Bubble Cap Trays are used for low liquid loads & very high turn down ratios.

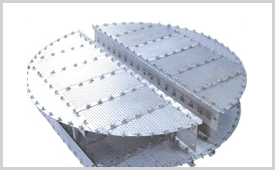

Sieve Trays

Sieve Trays consists of flat perforated deck. Passage for the vapours is through holes provided. The vapour pressure is such that it prevents liquid into the perforation. These trays have good capacity and moderate efficiency. Sieve Trays have low maintenance cost.

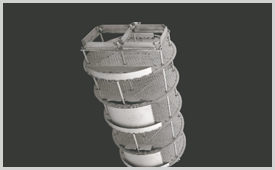

Cartridge Trays

Towers with small diameters, prohibiting installations of trays though man holes require Cartridge Trays to be installed. These trays are connected together to form bundles for easy installation. These can be sieve trays, valve trays or bubble cap trays as per system requirements.